1. Our product is a small straight glass encapsulated thermistor temperature sensor.

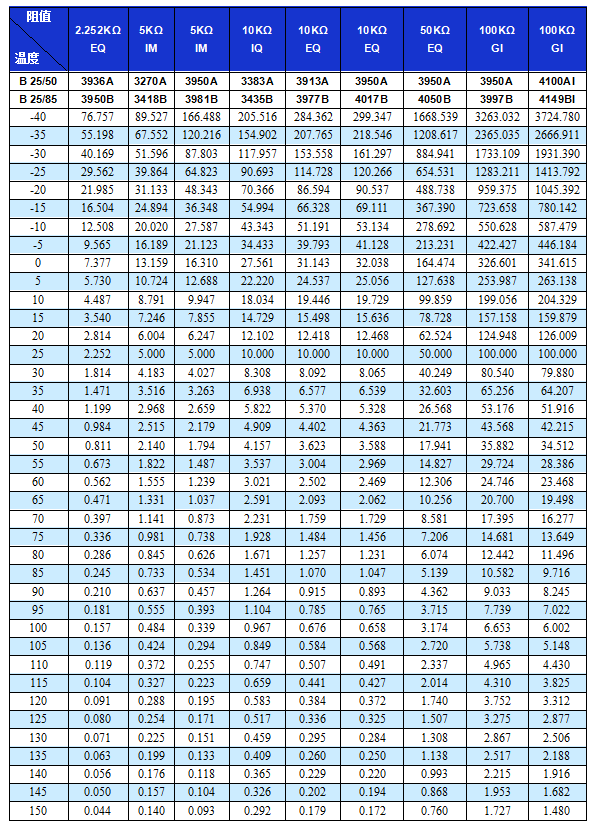

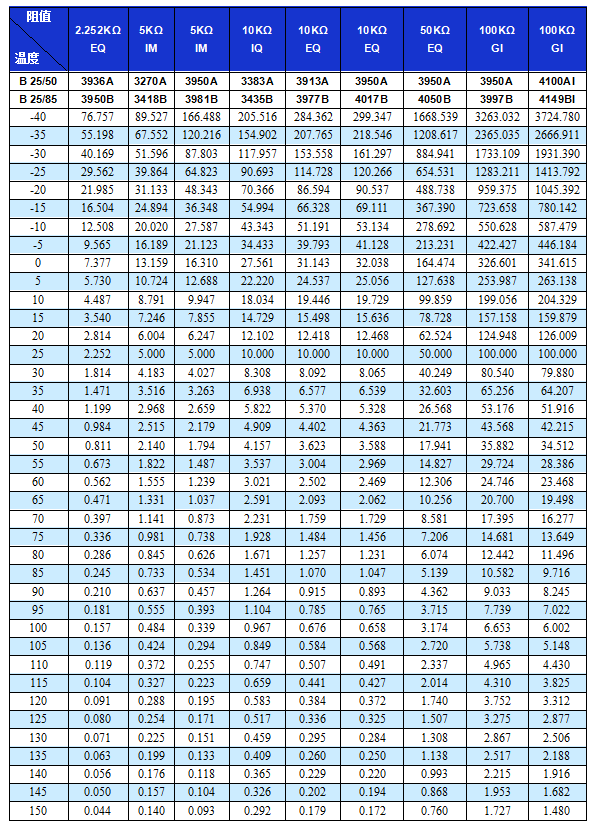

2. It has a wide range of resistance values, from 1KΩ to 1000KΩ, and high accuracy in both resistance value and B value.

3. This sensor is suitable for use in harsh environments, such as high temperature and high humidity, due to its glass encapsulation.

4. It is easy to automatic installation with a small size and strong structure. The sensor has fast heat sensitivity and high sensitivity, among other features.

(1)Temperature sensors play a vital role in 3D printing by monitoring the temperature of the extruder nozzle.

(2)The nozzle must be maintained at the proper temperature to ensure that the filament material melts and flows correctly through the nozzle.

(3)The temperature sensor provides feedback to the printer's control system, allowing it to adjust the nozzle heater to keep the temperature within the optimal range for the material being printed.

(4)This improves print quality by preventing under- or over-extrusion due to temperature fluctuations during printing.

(1)The print bed temperature sensor is another important temperature monitoring component in a 3D printer.

(2)Many materials, such as ABS and nylon, require a heated print bed to prevent parts from warping and delaminating from the print bed.

(3)A bed temperature sensor provides closed-loop control of the heated bed to maintain optimal adhesion temperatures throughout the printing process.

(4)This eliminates the risk of overheating when printing materials that require a higher bed temperature.

(5)The proper bed temperature improves the adhesion of the first layer and prevents shifting or peeling during the printing process.

(1)Some industrial 3D printers also use an enclosure temperature sensor. materials such as ABS and nylon print best at a stable enclosed chamber temperature.

(2)The enclosure sensor provides feedback to adjust the heater to maintain the desired chamber temperature.

(3)This reduces cooling and shrinkage effects that can cause parts to warp.

(4)It also prevents airflow that could disrupt layer bonding. Maintaining a stable closed print environment temperature is critical for large ABS and nylon prints that minimise defects.

Ordering instrctions

1. Our product is a small straight glass encapsulated thermistor temperature sensor.

2. It has a wide range of resistance values, from 1KΩ to 1000KΩ, and high accuracy in both resistance value and B value.

3. This sensor is suitable for use in harsh environments, such as high temperature and high humidity, due to its glass encapsulation.

4. It is easy to automatic installation with a small size and strong structure. The sensor has fast heat sensitivity and high sensitivity, among other features.

(1)Temperature sensors play a vital role in 3D printing by monitoring the temperature of the extruder nozzle.

(2)The nozzle must be maintained at the proper temperature to ensure that the filament material melts and flows correctly through the nozzle.

(3)The temperature sensor provides feedback to the printer's control system, allowing it to adjust the nozzle heater to keep the temperature within the optimal range for the material being printed.

(4)This improves print quality by preventing under- or over-extrusion due to temperature fluctuations during printing.

(1)The print bed temperature sensor is another important temperature monitoring component in a 3D printer.

(2)Many materials, such as ABS and nylon, require a heated print bed to prevent parts from warping and delaminating from the print bed.

(3)A bed temperature sensor provides closed-loop control of the heated bed to maintain optimal adhesion temperatures throughout the printing process.

(4)This eliminates the risk of overheating when printing materials that require a higher bed temperature.

(5)The proper bed temperature improves the adhesion of the first layer and prevents shifting or peeling during the printing process.

(1)Some industrial 3D printers also use an enclosure temperature sensor. materials such as ABS and nylon print best at a stable enclosed chamber temperature.

(2)The enclosure sensor provides feedback to adjust the heater to maintain the desired chamber temperature.

(3)This reduces cooling and shrinkage effects that can cause parts to warp.

(4)It also prevents airflow that could disrupt layer bonding. Maintaining a stable closed print environment temperature is critical for large ABS and nylon prints that minimise defects.

Ordering instrctions

JEPT INTERNATIONAL LIMITED is established in2005, which relies on the advantages of core technology and patented products......

CONTACT COMPANY

+86-769-88068888

+86-15622503218

sales@jpet.cn

243700158

Copyright © 2022 GUANGDONG JEPT TECHNOLOGY CO., LTD Technical Support : Leadong Sitemap 粤ICP备16023198号-4